Your All-in-One Solution

For Streamlined Inspections and Centralized Defect Management

Standardize inspection procedures and collaborate with internal teams and external vendors

Plan, assign, and track inspection and remediation tasks with full visibility and accountability.

Identify, document, and prioritize findings with photos, notes, and structured fields.

Verify remediation, attach evidence, and ensure nothing is closed without validation.

Generate inspection and closeout reports in one click and automatically sync them with your ERP.

Powerful Features

To Take Control of Your Assets

Standardized Inspection Workflows

Create and manage consistent inspection procedures across teams and contractors.

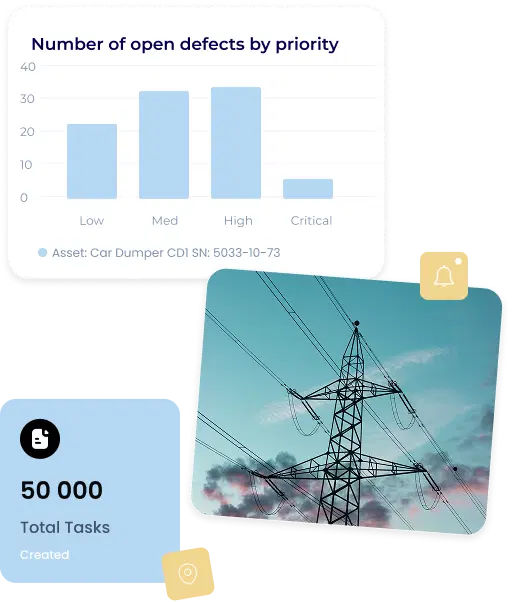

Dashboards & Reporting

Track team performance in real time and get inspection and remediation reports instantly.

Defects & Observations Management

Capture, classify, and document defects and observations with photos, notes, and evidence.

Regulatory Compliance Tools

Generate audit-ready reports

ERP Integration (SAP, Dynamics, Odoo)

Push summaries of completed inspections and closeouts directly into your ERP.

Offline-Ready Mobile Inspections

Work in the field without connectivity and sync data automatically when back online.

Importance

of Asset Management

Asset management has become a mission-critical function across asset-intensive industries such as oil & gas, mining, energy, utilities, transportation, and industrial infrastructure. Organizations operating complex, capital-heavy assets often face harsh operating conditions, strict safety requirements, and increasing regulatory and environmental pressures. In this context, effective asset management is essential to ensure operational reliability, cost control, and long-term value creation.

As asset owners and operators seek to optimize performance and extend asset lifecycles, modern asset management systems are no longer optional. Proper management of physical and non-physical assets—including equipment, facilities, infrastructure, and operational data—enables organizations to reduce unplanned downtime, improve maintenance efficiency, and control operational risk. At the same time, structured asset management supports regulatory compliance, audit readiness, and sustainability objectives, making it a strategic foundation for resilient, efficient, and future-ready operations in the world’s most demanding industrial environments.

Moreover, with the growing emphasis on sustainability and resilience, asset management now plays a key role in ensuring that assets are used responsibly, contributing to environmental and social goals while meeting organizational objectives. This is especially important in sectors such as energy, where the transition to cleaner technologies and the management of aging infrastructure present both challenges and opportunities.

The 2024 revision of ISO 55001 responds to these evolving challenges, offering a more integrated approach that aligns asset management with broader organizational goals. It emphasizes not only the optimization of assets but also the importance of risk management, continual improvement, and a more sustainable, resilient approach to managing the entire asset lifecycle.

Get Started

In 4 Easy Steps

Prepare the Inspection

Create a structured inspection document with all required steps and checklists to ensure consistency and compliance

Execute & Capture Defects

Start the task and capture defects in the field using photos, GPS data, and predefined templates linked to the inspection.

Review & Validate Defects

Review existing and newly identified defects for the same asset to avoid duplication and ensure accurate tracking.

Close & Report

Finalize the task and automatically generate completion reports. Defects can be exported or converted into remediation documents and sent to your email or ERP system.

Request a demo